The large viewing window allows you to bask in the warm glow.

The large viewing window allows for an unobstructed view of the glorious flames within.

Customisable

Choice between Log effect and Coal Effect Fuel Beds.

Natural Gas OR LPG

LPG

Heat Output: 2.5kW – 4.5kW

Gas consumption (m3/hr): 0.244

NOx Class: 5

Efficiency class: 2

Natural Gas

Heat Output: 2.8kW – 4.4kW

Gas consumption (m3/hr): 0.619

NOx Class: 4

Efficiency class: 2

Efficiency: 75%

Energy efficiency rating: E

- 5" Flue

- Remote Control

- Black Handle

Optional:

- LPG OR Natural Gas

- Coal OR Log Effect Fuel Bed

- Single Door OR Double Door

Fuel Type: LPG OR Natural Gas

Body Type:

Freestanding

Design:

Contemporary

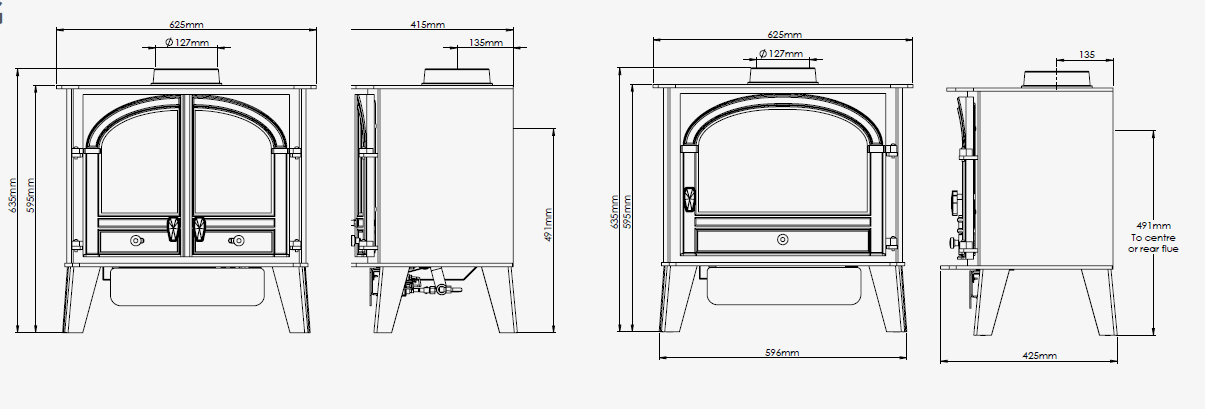

Flue Diameter:

127 mm / 5"

Flue Outlet: Top

Features & Technologies Explained

Hunter Stove Group’s unique Cleanburn (Tripleburn)technology improves efficiency and combustion. It works by utilising three streams of air (Primary, Secondary & Tertiary) which provides optimum air flow into the stove. The primary air stream is directed underneath the grate/fuel bed and into the heart of the fire, allowing for a clean & efficient burn. The secondary air stream is the hot air wash, which maintains a protective stream of air between the glass and the fuel, reducing the build-up of carbon deposits. The tertiary air stream comes in from the back of the stove and reignites un-burnt gases for a more clean and efficient burn.

Air wash technology allows air to flow over the glass providing a protective layer and aids in cleaning your glass.

MULTI FUEL ONLY. There are two grate settings to allow for optimum burning conditions for fuel. When the grate is closed it creates a flat base and allows ash to build up, creating optimum wood burning conditions. When the grate is open it allows ash to fall through and increases the air flow, which increases the efficiency on smokeless fuel. The grate can also allow the fire to be riddled in order to reduce the amount of ash on top of the grate.

Defra Approved means the stove compliant with regulations for smoke controlled areas. If you are unsure is your area is smoke controlled this can be found out from your local council.

Generally air bricks are required for a stove over 5kW however this can vary depending on the manufacturer’s recommendations.

A nominal output is the output where the stove is at its most efficient, this was found out by the manufacturer during the testing phase. The output ranges are the minimum and maximum outputs the stove can get to without causing it damage.

If you are interested in finding out more about these stoves or would like to enquire about a price please contact us. You can either visit one of our team in the showroom, call us on 01406 373600 or email us at flamecraftuk@aol.com